Tires are an important piece of kit for trips like this, and in my case the subject of much thought – not so much about which tires to use, but whether I should take a set with me or not.

I had decided that I would ride Europe in the tires I already have – a set of Michelin Anakee 2, they have plenty of thread left and lots of people have got very hard mileages out of them – and then swap them for a set of Heidenau K60s in Volgograd before starting the roughest part of the trip.

Most people say that it is hard to find the sizes I need for my bike in Russia, let alone Kazakhstan or Mongolia, so I could find a workshop when the moment came to change them and wait for them to order and have a set delivered, I could buy a set myself and send them ahead of me for them to be ready when I got to Volgograd or I could carry them with me from the start.

Waiting for tires to be delivered was not an option, since I do not want to spend any longer than necessary unless there is a problem, and forwarding them required having a contact in Volgograd to pick them up and store them, and they might be made to pay import taxes upon delivery. I imagine I could have arranged that through the HUBB, but it was too much hassle and I liked the idea of having a couple of spares with me if a puncture can not be easily fixed with a repair kit. I could always limp to or arrange to have the bike transported to the nearest workshop and have the tire changed.

So having made the decision to take the tires with me, I spent the weekend studying different ways to secure them to the bike.

I carry my camping/cooking equipment on one pannier; the tools, repair kit, spares, maintenance kit on the other; the paperwork, important items, laptop, camera, etc. on the tank bag and the clothes, first aid kit and sewing kit on a waterproof rack bag.

I quickly discarded the option of hanging the tires on the back of the bike – it pushed the CoG too far back and there are already a jerrycan and oil and grease bottles back there, not to mention that they would partially cover the rear light or the exhaust or the license plate depending on the position.

I have not fitted any tank saddlebags and I had seen pictures of a guy who had slung his tires over the tank and had them hanging on both sides of the bike. I tried that, but they are too big and when strapped tight they interfered with either my legs or the front wheel.

So they would have to share the rack and passenger seat space with my rack bag.

I tried different positions – the bag first and the two tires vertically behind it, the other way round, one tire standing behind me and another at the back, with the bag in between, one tire standing, the other flat and the bag on it, even have the tires standing on the panniers and the bag fitted through them… All positions looked awkward and had several disadvantages – water would accumulate on the inside of the tires, they stood too tall, I would have to remove them every time I wanted to take something from the bag or the bag itself (and that’s every single day)…

I did not want to have to remove them until the moment came to use them, the idea was to strap them securely and then lock them to the rack with a cable and a padlock the make them harder to steal. In the end then, the best position was to lay them flat and put the bag on top of them.

There were two thing I did not like about this option – the whole thing was rather tall (it almost reaches to my shoulders) and there was a big unused space inside the tires. However, after some thinking I found a good compromise.

I was going to carry my provisions inside the rack bag (I got it big because I did not want to carry too many smaller ones), but if I used the space in the tires to carry them the bag would be emptier. Not only that, but the stuff inside would be easily compressible (mostly clothes) so it would flatten more against the tires and enable me to roll the top of the bag more times, thus making it more waterproof. It was decided.

Lying flat on the seat and the rack, the tires took quite a lot of space, and if I sat comfortably without them touching my back, the were a couple of cm too far back, so they did not rest on the rack, which meant I had to do something to support them there. I had removed the top case but I had not fitted a base to the rack, there was only the original one, and I did not want to pay through the nose for a rack extension just to have one end of the tires rest on it, so I decided to make my own tire rack.

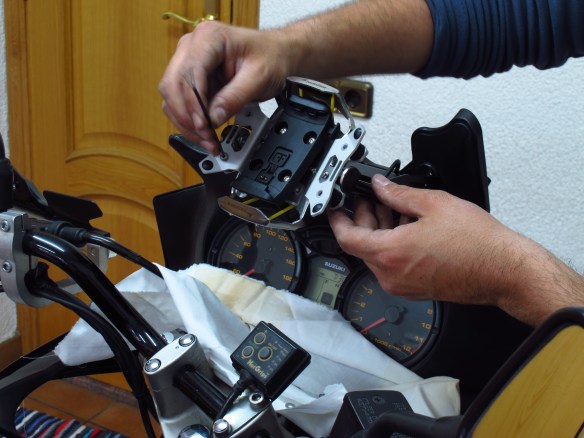

I got a couple of L section steel rails – aluminum was lighter, but it was too flexible, and the steel rails are very strong for what they weigh – and started to work on them to make them fit the mounting points on the bike rack.

I have to say that I had the privilege of having my father’s assistance and advice on this, a natural-born engineer (and one of the best I know, at that) so for the price of a couple of bits of metal and a few hours of work in great company I got a perfect custom-made tire rack. Suck that up, Touratech.

We cut them to the appropriate length, filed off the edges, shaped the lower side to make it fit flush with the bike rack without losing any structural rigidity and drilled the mounting points and while we were at it, a whole at each end that makes a handy attachment point.

Apart from that, I also spent some time improving/customizing the Touratech panniers. I had got four padlocks to lock them and they are great – light and they are all opened with the same key, but in only two days riding around they had started to scratch the aluminum, and they rattle as hell between 5 and 6k rpm, which is the usual working range of the bike…

So I got some adhesive foam and cut four protectors to stick under them. I also got some reflective tape to put at the back of the panniers, I want to make myself well visible, especially in those parts of the world where drivers are not as used to the presence of motorbikes as in Barcelona.

Finally, I got some cheap bicycle bottles and bottle holders and fitted them to the front of the panniers. I hope the air stream will keep them cool and they will make a nice extra supply of water for the harder parts of the trip.